Also known as a wood bit, a brad point bit is designed to bore neatly through the wood.

While standard twist bits may not drill accurately, especially at the beginning when it skates across the surface of the wood, the brad-point is quite accurate and smooth.

The brad point itself consists of a sharp point at the end of the drill.

This allows for great accuracy when drilling a hole, especially when helped by the spurs that continue to cut into the wood fibers.

How Does Brad Point Drill Bit Work?

The first part of the contact with the wood is the brad-point itself. Because it is quite sharp, it digs into the grain of the wood immediately.

The result is that the drill bit cannot move or skate around as standard twist drill bits can.

As the bit moves further into the wood, the spurs located on the edge of the twist bore into the wood.

This means that the spurs cut the circumference of the hole neatly so that the wood fibers are not pressed or bent during the drilling process.

Instead, they are cut clean, which creates a neat hole in the wood.

After the spurs go into the wood, the lip of the drill bit descends into the material. This means that any waste left behind by the spurs is quickly cut away.

The result is a very neat hole as the excess material is pushed up through the flutes and exits the borehole.

The edges of the hole remain clean as the spurs continue their descent. Because of the spurs, splinters do not form as the wood fibers are continually being cut.

The brad point drill bit operates on the same principle as the bits made of tungsten carbide or polycrystalline diamond-tipped drill bits that bore into Kevlar.

Kevlar, like wood fibers, is a tough, fibrous material that can be cleanly drilled into using the right drill bits.

The brad point drill bit is designed to cut into wood in the same manner.

The result is a clean hole that has no loose, exposed fibers. This means that the hole left behind is clean and ready for use.

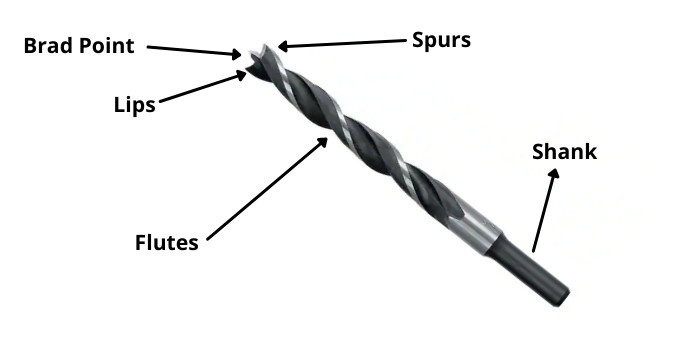

Parts of a Brad Point Bit

There are five basic parts of a brad point bit. Each part serves a specific function in how the drill bit operates.

a) Brad Point

This is the sharp end of the drill bit itself, the point from which the name is derived.

The brad point will protrude from the center point of the drill at a further distance compared to the spurs.

This allows the tip to immediately grab the wood fibers and hold the drill in position.

b) Spurs

These are sharp barbs located on the outside of the bit at the top.

They are not as long as the brad-point itself, but they do sever the wood fibers as they dive into the wood itself.

The result is a clean, neat hole that is perfect for bolts and other fasteners to be used.

c) Lips

The lips are at the top of the flute, just inside the spurs. They are designed to cut away any material that the spurs do not get.

Acting like a chisel, the lips cut out the waste material and send it up the flute so that it can be ejected from the hole.

d) Flutes

The flutes on a brad point drill bit tend to be wider compared to standard twist bits of the same dimensions.

This allows for more material to pass through the flutes without it becoming clogged.

The angle of the flute is shallower on a brad point drill.

With the steeper incline, the shavings or waste material moves through the flutes at a faster pace.

This reduces the likelihood of clogging to a considerable degree.

By moving the shavings out of the borehole, it reduces friction which in turn keeps the temperature down.

Otherwise, a drill bit that got too hot from becoming clogged would also lose its tempering. And that makes the drill bit rather useless.

e) Shank

This is the part of the bit that fits into the drill driver.

As with other bits, the brad-point bit is designed to be used with numerous power drills.

While most of the shanks of a brad point bit are round, you can find other shapes that include hexagonal.

Different Types of Brad Point Bits

There are two basic types of brad point bits. One is designed for hardwood, while the other is designed for softwood.

The reason for the two different types of bits is simple. The grain of hardwood is quite tough and requires a sharp edge for it to be cut properly.

A softwood grain may tear apart when creating a sharp edge, so it needs a different shape of bit to make its way through the grain and fibers.

Hardwood:

The spurs on the brad-point bit are angled downward so that the points will go into the wood shorter after the brad-point at the top of the bit.

They slice into the grain in a neat and efficient manner while reducing the amount of friction and heat which is experienced.

Because of the sharp spurs, you can use this type of brad-point bit on other materials.

Softwood:

The points on the spurs are not angled in a downward manner such as on the hardwood version.

They follow the angle of the lip and are rounded off.

The result is that a greater amount of the spur will contact the wood compared to the sharp spike of the hardwood brad point bit.

With the pressure being applied wider and more evenly, the bit goes into the wood without ripping apart the fibers.

It is true that using a hardwood bit on softwood may not be that problematic.

This is especially true if you are drilling holes for dowels to be inserted.

While the reverse side of the wood may blow out when using a hardwood bit on softwood, there are techniques you can use to prevent this from happening.

However, you should not use a softwood bit on the hardwood.

With the grain offering greater resistance, the friction will build up quickly, causing the bit to overheat. This may even char the borehole along with making the bit useless.

What are Brad Point Drill Bits Used For?

Brad-point bits are primarily designed to create clean, neat holes in wood.

Brad-point bits are far more accurate compared to the standard twist bit.

The point and spurs keep the bit running straight through the wood without slipping or skating across the surface.

When precision is needed when drilling holes in wood, the brad-point bit is what is required.

For drilling dowel holes, the brad-point bit is highly recommended.

Its accuracy, combined with the smooth hole it creates, makes it easier to place the dowel properly in the hole that is created.

In addition to wood, brad point bits can also be used on other materials such as thin sheet metal, fiberglass, and even plastic.

You can even drill through graphite using a titanium carbide brad-point bit or a bit with a polycrystalline diamond tip.

You’ll also find brad point bits used in aviation as they can bore through carbon fiber thermoplastic that has been reinforced with aramid fiber.

This rigid material consists of different layers and is often used in the construction of airplanes.

How to Use a Brad Point Bit for Your Project?

It should be noted that one of the strengths of brad point bits is that they are easier to control compared to many other bit types.

This means that most projects will be completed faster and with neater results in terms of boring holes.

Even though brad point bits are less prone to blowing out the reverse side of the material compared to traditional twist bits, you will need to support the reverse side by placing it on a piece of scrap wood.

This will allow you to drill through the wood and stop before hitting the table. Plus, the support it offers will keep the hole neat on the reverse side.

A pro tip is to use scrap wood that is of a different type than the wood you are using for your project.

You can feel the change in resistance when boring into the scrap wood, so you know when to stop.

If you do not have the appropriate scrap wood, then you can use the technique of stopping the drill just before it exits the wood, then flip the wood over and drill from the other side using the hole made by the brad-point as a guide.

Why Choose Brad Point Bits over Other Drill Bits?

There are definite advantages to using a brad point bit compared to traditional twist bits when working with wood.

They can also be used on other materials as well, though they have their limitations.

- Neat, Accurate Holes

- No Splintering

- Versatile: Can be used on plastic, fiberglass, and thin sheet metal

- Less prone to blowing out the reverse side of the material

However, the brad-point bit is not perfect for all situations.

The first downside is that this type of bit is basically impossible to sharpen without ruining it.

Brad-point bits are also more expensive compared to standard twist bits.

And the cheaper ones tend not to be that good.

And while they are less likely to cause a blowout on the reverse side of the material, it can happen if you do not take precautions.

This is because the sharp edge that bores into the hole may still push the material downward and cause it to fracture just as the drill is exiting the other side.

Brad-point bits compare well with traditional twist bits.

Although they are not as wide as spade bits, which you may want to use you need to make an extra-wide hole.

Brad-point bits are also smaller and thinner compared to Forstner bits which makes them cut into the material at a faster rate.

Brad-point bits are also smaller compared to auger bits. This makes the brad-point bit easier to control.

Overall, a brad point bit offers considerable advantages when working with wood and certain other material.

Its unique design makes it quite usable for projects involving wood, thin sheet metal, plastics, fiberglass, and more.

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.