Many different tools are available for various projects around the house or job sites. Among these specific tools is a door and board lifter. Its name seems pretty self-explanatory, as it is used to pry up various rigid sheet materials.

A door and board lifter is a tool designed specifically to hold and lift doors, panels, or any other types of sheet material during the time they are being fitted.

The lifter is designed to let one person fit the panel, a job that would otherwise take two people without such a tool.

Read on to learn more about the door and board lifters, including what they’re made up of, used for, and how to use them properly…

A Brief History

Door and board lifters are believed to date back to prehistoric times. They are believed to have been used by Ancient Egyptians to raise their obelisks, which often weighed more than 100 tons as they were made from solid stone.

The first recorded written mention of them was in 260 BC by Archimedes, an ancient Greek inventor.

He is famously quoted as saying, “Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.”

What is it Made of?

Because door and board lifters are used with heavy materials, they need to be pretty durable and strong.

They are usually made of materials that are built to withstand use for long periods of time for this reason. Some of the materials used to make these carpenters’ door lifters include:

a) Steel

Steel is a metal that is famous for its superior strength.

Door and board lifters that are made out of steel should be quite strong, but their material composition might make them difficult to carry because of their weight.

Steel is also likely to rust if it is exposed to moisture, but the risk is lessened if it is painted or otherwise coated.

Steel is often pricier than other materials, such as plastic, but its high-quality, long-lasting properties usually make it worth the price to contractors.

That said, it is usually cheaper than using high-grade aluminum to make them.

b) Aluminum

Aluminum is also a strong metal, though it doesn’t have the same level of strength that steel is known for.

It is also much lighter than steel. As stated above, quality aluminum is usually more expensive than steel.

c) Plastic

The final common material used to make heavy door lifters is plastic. Plastic is usually the weakest, cheapest, and lightest material used to make them.

Even so, there have been advances in plastic technology that make some plastic products stronger than others. This new kind of plastic lifter may be stronger than the alternatives but will also come at a higher price.

Which material is best to choose?

When deciding which material your new lifter should be made of, you will need to consider how often you plan to use it, the weight of the material that needs to be lifted, and the amount of money you want to spend.

The quality of the board lifter will also influence the lifter’s strength.

With a high-quality lifter, you’ll likely pay a higher price but will be able to use it for longer and for many types of projects.

On the other hand, cheap plastic lifters are not as durable, but higher-priced plastic lifters have the potential to be quite strong.

High-quality aluminum is costly, but it is both strong and lightweight. If you choose cheap aluminum, it might be weak in comparison.

Steel is a durable option that is relatively cheap comparatively, but its weight can make it hard to move around and work with.

The Parts & Features

Many doors and board lifter tools have simple construction, and some of them are more complex with extra add-ons that make them more effective.

Below are the most common parts of a door and board lifter:

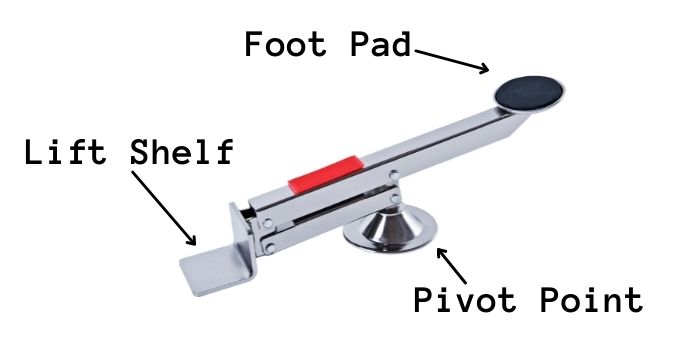

1- Foot Pad

The tool is usually operated using your feet so your hands can remain free. Applying pressure to the footpad will lift the shelf, which in turn will lift the item you’re working with.

They sometimes come with a non-slip surface that will give you a more secure handle on the footpad.

Generally, a non-slip surface on a footpad of a door and board lifter can give you better traction and make it easier for you to hold the lifter in place, thereby lessening the risk of it slipping.

2- Lift Shelf

A small shelf is positioned at the end of the tool designed to keep the object you are lifting well supported.

The shelf is more stable the wider it is, and the width will also determine how thick the item you are lifting can be. This shelf usually has a lip that keeps the item in place as it is lifted.

Some of these door lifter installation tools have a lift shelf that you can extend. When the shelf is extended, you can use it to lift an item even higher than it would go when used in its original position.

Keep in mind that extending the shelf will lift it further away from the pivot, meaning more effort will be needed to lift the weight.

3- Pivot Point

This is the aspect of the tool that stays on the floor. Some of the pivot points are made to stay in one place, while others swivel and roll, making it easier to adjust them as you use them.

A lifter with rolling pivot points can move the sheet material across any surface while lifting it.

This can save you plenty of time if you need to make any small adjustments to the position of the item.

A traditional lifter will usually have to be moved by hand in order to get it into the right position, which can be difficult and time-consuming.

A Few Additional Features

These tools also have different features that can be used to make them more effective.

The features you will find the most beneficial should depend on how often you use the lifter and for what material.

However, keep in mind that lifters with extra features are often pricier than standard ones.

additional-features-can-door-and-board-lifters-have

Ratcheted Lock

This lifter is often known as a lift and lock tool. It will lock into position when you take your foot away and stay there at that height.

In this way, you can move away from the tool while it remains in place. The lock can be disengaged just by pressing the release lever.

Foot Guards

Many doors and board lifters feature a strip of metal that arches over the top of the foot and serves as a foot guard.

This helps to keep your foot in place as you use the lifter, and it can commonly be adjusted to fit different types and sizes of footwear.

Hanging Hole

Finally, many kinds of board and door lifters will have a hole along the end of the footpad.

This hole can be used to hang up the lifter, allowing you to safely store it out of the way when not in use.

Besides the above, there are built-in accessories on some door and board lifters that allow them to be used as different kinds of tools.

This includes lifters that allow you to smooth the edges of the cut plasterboard using a pasteboard clasp.

Other common accessories include plasterboard hooks that let you adjust a plasterboard sheet when fitting it into place.

The hook lets you reach the end of the board more easily, and you can hook the edge of it with a lifter and then use it to position it where it belongs.

How Do Board Lifters Work?

Board and door lifters are considered to be first-class levers. This allows you to lift and keep hold of a heavy sheet material that is a few centimeters from the ground.

This tool helps reduce the amount of effort and exertion required to hold up rigid sheets and doors as you work with them.

The lift shelf fits right under the sheet material while, at the same time, your foot presses the footpad. The result is the lifting of the sheet.

Once the material is lifted to the desired height, some lifters allow you to lock them into place, while others require you to keep your foot in place as you work.

Levers are simple machines that are incorporated into projects that need their input method amplified, resulting in a greater force of output. There are three kinds of levers, first-class, second-class, and third-class.

Each has different positions for the pivot point, output force, and input force. You’ll find that a first-class lever positions the pivot point between both the output and input forces.

The efficiency that first-class levers provide is thought to be a “mechanical advantage.”

This advantage gets a boost by elongating the distance between the pivot point and the input point while lessening the distance between the pivot point and the output point.

This mechanism is reflected in the construction and design of many board and door lifters.

What Are Door and Board Lifters Used For?

Door and board lifters are used for two primary purposes, fitting plasterboard, and fitting doors:

Fitting Plasterboard

Also known as wallboard, drywall, and gypsum board, plasterboard is a common material used with this tool.

These boards are used to create the lining of ceilings and interior walls and are installed flush against the ceiling instead of the floor.

It is a much faster alternative to using traditional plaster, as it takes a long time to dry completely.

Fitting Doors

Above all, door and board lifters are commonly used to fit doors since they need to clear the floor to be able to open easily and freely.

Doors are usually quite heavy and can be hard for just one person to handle. Using a lifter, you can keep both hands free to work while the door stays lifted with the help of the tool.

How to Use?

To use a door and board lifter correctly, you can follow these steps…

Step 1 – Position the lifter

Slide the door and board lifter into place beneath the material you are lifting.

Be sure the material is properly positioned on the shelf. The item will usually achieve a better balance if you position the shelf in the middle of the material.

Step 2 – Raise the door

Using your foot, press down on the footpad to raise the lift to the desired height, keeping the material supported with your hands.

Some lifters let you swivel or roll the material into the right position. Other door and board lifters will require you to put it in a roughly accurate position before you lift it.

This will also require you to adjust it by hand.

Step 3 – Fit the material

After the material has been lifted to the proper height, you can hold it in place by not lifting your foot.

If you have a lifter that can lock into a set position, you can engage it now. Both options will leave you with your hands – free to work.

Tips for Maintenance and Care

A door and board lifter is relatively simple to use and doesn’t require much maintenance. This is true so long as you use it within its requirements.

Even so, there are a few ways you can maintain the lifter.

First of all, if there is any dirt on the lifter, it is recommended to clean and completely dry it before you store it to lessen the risk of rust.

Also, it’s good to oil the moving parts before you store them. Any moving parts in the lifter will benefit from occasional oiling, helping to extend its useful life.

What Can You Use as An Alternative to A Door and Board Lifter?

If you don’t think you need to use a board and door lifter often, there is a chance you can find something else lying around to use instead of buying a special tool for that exact purpose.

So, fortunately, there are a few different alternatives you can consider:

a) Pry Bars

Pry bars are levers similar to door and board lifters, though they should be used with a scrap piece of plywood or something like it to protect the floor.

The thinner end of the pry bar can be used in a similar manner as a board and door lifter in order to lift sheet material off the floor.

Pry bars are easy to adjust with your hands. You can also adjust them with your foot to ensure both hands stay free.

b) Brick Bolster Chisels

This kind of chisel tool is made to break bricks open; you can be sure they are durable enough to support a door or other kind of rigid panel.

They feature wedge-shaped edges that can easily be placed beneath sheet material.

Using a small piece of wood beneath the bolster, you can use it similarly as a board and door lifter to lift it from the floor.

c) Air Wedges

This type of wedge is flat, so you can easily slip them into narrow spaces.

They feature a hand pump that you use to inflate the wedge, and it can usually be inflated to approximately 50 millimeters.

At this size, they can withstand a load pressure of approximately 100 kilograms.

After you inflate them, you can lock them into place to ensure they don’t lose air and then leave them in place.

d) Door Stands

A door stand is used when you need to clamp a door and hold it in place while carving lock recesses or hinges into it.

This kind of stand can also be used to fit and tilt a door to the frame itself.

That said, they usually have a weight limit of 50 kilograms and cannot be adjusted to a different height.

e) Board Lifters

These lifts are usually referred to as mechanical door and board lifters but sometimes can also be called plasterboard lifters or board hoists.

They can lift sheet material a lot higher than a traditional door and board lifter and are also capable of being angled into a number of different positions.

They are also used to fit plasterboard against ceilings.

f) Door Installation Carts

Known also as door jacks and door handlers, this versatile tool is quite similar to a door and board lift.

They can hold sheet material in order to tilt and elevate it into place while fitting. However, they don’t often lift as high as a board lift.

They are considered to be more specialized than a traditional board and floor lifter and are commonly used with super-heavy industrial doors.

Share the post "What is a Door and Board Lifter – How to Use it Correctly?"

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.