A rotary tool is designed to carve, engrave, route, clean, polish, cut, sharpen, sand, and grout removal.

“Dremel” is the manufacturing brand for one such rotary tool.

But the company has become so famous in the field that it is often called a Dremel rotary tool.

Understanding how to properly use a Dremel rotary tool will help you in creating the precise cuts needed through materials such as wood or drywall.

However, such cuts may require a specific type of attachment depending on the type of cut that is being made.

Knowing what to add will help you make a better cut into the material.

You can purchase a Dremel rotary tool alone or as part of a cutting kit that offers a variety of attachments.

If you do not have any attachments, then purchasing the cutting kit may be a smart decision.

This is because different cuts and different materials will require different attachments.

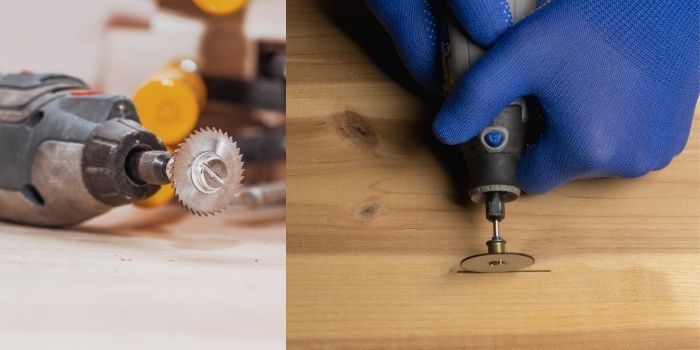

Straight Bit or Cut-Off Wheel

These attachments are used when the material is less than a half-inch in thickness.

If the wood you are cutting is thicker than a half-inch, then you will need to purchase a bigger tool.

A straight bit, as the name suggests, is better at making straight cuts.

But cut-off wheels are commonly used for many different types of cuts, grooves, or circles.

Cutting Wood with a Dremel Rotary Tool

Before you begin cutting with your Dremel rotary tool, you will need to have the right safety equipment on hand.

This includes gloves designed to reduce heat and friction, which may injure exposed skin.

Other safety equipments recommended for use with the rotary tool include the following.

- Face Mask

- Safety Glasses

- Ear Plugs

The face mask and safety glasses, when used in combination, maximize the protection of your eyes from any flying debris.

The earplugs are used to lower the noise level. This is because a typical Dremel rotary saw and the wood it cuts through are going to be loud during the operation of the device.

Step 1 – Preparation

Once you have the safety gear, the material, and the tool ready to go, you will need to prep the area in which you will be working.

This means where you cut should be open and well-ventilated.

In addition, the material will need to be cut on a workbench that has clamps to secure the material as it is being cut.

Step 2 – Choose the Right Bit

The choice of what bit to attach will depend on the material you are using and the type of task you are performing.

If you are drilling, then use a drill bit. Router bits can be used for simple tasks.

If you need it specifically for cutting wood, something like the Dremel 561 bit would be ideal, which can cut hardwood up to a thickness of 3/8″ and softwood up to 5/8″.

Also, you can consider investing in a carbide cutting wheel which is great for cutting through the toughest pieces of wood.

However, if you are engraving or carving, then you will need a more specialized bit, such as the following types of cutters.

- Diamond Wheel Points

- Engraving

- High-Speed

- Structured Tooth Carbide

- Tungsten Carbide

With that completed, you should place the appropriate attachment on the Dremel rotary tool and secure it for cutting wood boards or 2x4s.

This means removing the collar and attaching the router base, which should include the straight bit for cutting.

To do so, simply insert the straight bit into the hole at the end of the tool, then back it in slightly.

Now, tighten the collar nut that secures the bit into place.

Remember that you can replace bits by pressing downward on the lock button on the tool shaft.

You will need to turn in the collet to do this task.

Once the bit is loosened, you can remove it and replace it with another bit.

When removing and inserting bits, be sure to unplug the power first, and the rotary tool needs to be shut off.

Step 3 – Mark & Cut

To create the most accurate cut using the Dremel rotary tool, you will need to accurately mark the area that will be cut.

This means using a stencil or marker that provides the lines needed for you to follow with the rotary tool.

It is best to make the mark along the wood grain, as the Dremel rotary tool works best when pressed in the direction of the wood grain.

Otherwise, you might skip over some areas of the surface, which may make for an uneven cut.

Now you are ready to make the cut.

If you are removing a considerable amount of wood first, then using the saw attachment is the best option.

This lets you work with large materials and cut them down in a short timeframe.

You should not use a high-speed cutter unless the amount of wood needed to be removed is relatively small in area.

To prevent jamming, do not force or press into the material. Instead, use low pressure and let the bit do its work.

Also, remember that if you want to achieve a smooth cut, then you should select a higher speed and use wide strokes.

This will create a smoother cut compared to a slower speed which tends to create a rougher cut.

Step 4 – Remove Sawdust Frequently

The amount of sawdust will build up quickly and prevent you from seeing the work that needs to be accomplished.

You should frequently remove the sawdust so that you can see what you are doing.

Otherwise, you may wind up missing the marks you made and doing more work than you want to get the type of cut desired.

Step 5 – Sand or Buff

Once you have completed the cuts or notch as desired, it is time to use the sanding or buffing attachment.

This attachment will help smooth out the cuts you have made and remove any unevenness from the material itself.

By using the sanding attachment, you can retouch the areas that did not meet your satisfaction.

Can I Use a Rotary Tool to Cut Drywall?

If you want to cut drywall, a utility knife is the best tool for the job.

The spiral saw is also a great choice because it is simple to use and creates an accurate cut.

This is perfect if you need to cut openings for outlets and electrical boxes in drywall.

But if you want to use your rotary tool for cutting drywall, then you’ll need the correct bit.

The Dremel 560 and 561, for example, can cut not only plywood or 2×4 but also plastics, fiberglass, drywall, laminate, aluminum, and vinyl siding to as deep as 1/8 inch.

You can cut holes, detailed lines, etc., in drywall with a Dremel equipped with this drywall cutting bit.

Also, a Dremel is a great tool for cutting pipes that have specific curves and turns.

What Speed Can I Operate a Dremel Bit On?

Dremel has a range of different purposes to serve with their varied bit sizes.

While the ⅛” one is the most widely used bit size from Dremel, a few other common ones also include 1/32 inches, 1/16 inches, and 3/32 inches.

The thing you need to keep in mind while using these bits is they need to be operated at a specific speed for a specific project type.

The usual speed limit for using Dremel bits safely is 30,000 RPM.

But depending on the size, bit material, and project, this can go up to 32,000 to 35,000 RPM.

Do not forget to check your user’s manual to ensure you are not overworking your bit.

Can a Dremel Tool Be Used Like a Router for Rounding Off Corners?

Yes, it will do the job.

But remember, Dremel is not made for and is not the best option for these types of projects.

To get the round wood edges and rounded corners, a router will be much more powerful and can help achieve better results in seconds.

Dremel being a light-duty tool, can take a much longer time and will not give as smooth a finish as the router does.

Final Thoughts

Dremel rotary tool is an extremely versatile tool that fits nicely in your hand

It’s excellent for cutting, sanding, carving, and shaping small pieces of wood along with many other types of materials like plastic, glass, metal, and even wall.

However, to take the best advantage of this tool, it’s important for you to find the right accessory or tool bit that can serve your purpose.

Also, make sure you follow the right process as listed above.

Share the post "How to Cut Wood with a Dremel Rotary Tool – 5 Easy Steps"

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.