If you are looking for a hand tool that can provide a clean, smooth finish on your cabinet’s wood, then the cabinet scraper is the tool of choice.

A cabinet scraper (also called ‘card scraper’) is a simple yet powerful tool used to remove unwanted materials from a wooden surface while shaping, smoothening, and finishing the surface.

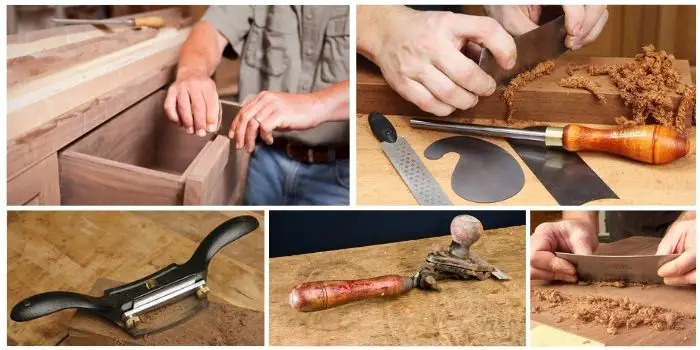

Traditionally, the cabinet scrapers come with a simple blade with no handle.

But today, more complex types and designs are available, making the tool most versatile in the woodworking industry.

While it may not be quite as smooth compared to sanding, it can actually make the sanding process go faster by providing a smooth surface first.

How does it Work?

The cabinet scraper has a hook or burr on each side. This means that the cuts are made when pushing the tool away from you at an angle or when pulling the tool towards you.

It can be used in a back-and-forth motion on the surface. The hook will dig into the surface and create wood shavings. The result is that the top layer of the wood is removed.

The shavings tend to be quite thin, so only so much material is removed when using this tool. You repeat the back-and-forth motion until you get a smooth surface.

You can make the surface even smoother by sanding if you desire.

Different Types

There are several different types of cabinet scrapers available. This includes custom-made types for specific jobs or materials.

What is listed here consists of the most common types of cabinet scrapers on the market today.

1- Convex & Concave: Both types of scrapers have curved edges, which allow them to smooth either convex or concave surfaces.

These scrapers usually come in sets of different sizes, so you can apply them to the exact curve of the furniture or other material you are trying to smooth.

Because of their relatively small size, you can use them to smooth items such as a molded skirting board, furniture legs, and even smaller items.

This is because they are well suited for delicate materials as well.

2- Flat: Otherwise known as rectangular scrapers, they are perfect for removing finishes and smoothing out flat surfaces.

It removes the unwanted materials one layer at a time, normally in shavings that can be discarded.

3- Gooseneck: With a body similar to a French Curve, this type of scraper is used to scrape the exterior and interior of surfaces that are curved.

The French Curve is the template that forms many different curves which can be used.

You can create the template out of metal, plastic, or wood and then use it to draw smooth curves.

The gooseneck scraper is well suited for curved areas of furniture. Plus, it can be used on more delicate wood, such as the fingerboards of violins.

4- Hollow: This type of scraper features two curved ends, one convex, which curves outwards while the other is concave and curves inwards.

You can use this scraper on objects that have hollowed or rounded ends where straight edges are not present.

The convex end is perfect for scraping-out bowls, for example. In contrast, the concave edges work quite well on the spindles of staircases.

5- Mini: As the name implies, these are small scrapers that allow for scraping convex or concave surfaces.

They are often held in one hand, although some are large enough for two-handed use.

A typical set of mini scrapers includes convex, concave, oval, gooseneck, and square scrapers with notches for fine work.

For smaller surfaces and precision scraping, mini scrapers are ideal when you want to do the job faster compared to sanding.

6- Quadrant: These are rectangular scrapers with the corners or quadrants cut out. The quadrants can be of different sizes.

This allows you to use the flat edge to smooth even surfaces while using the quadrant for molding, curves in furniture, and other items without having to change scrapers.

Quadrant scrapers normally come in sets, so you can choose the proper size for the item you are trying to smooth.

7- Two-Handed: As the name implies, these are scrapers with a handle on each side so both hands can be used.

Although it does look similar to a spokeshave, the blade for a two-handed scraper is thicker. In addition, the two-handed version is used to remove surface material.

While the spokeshave is used to shape wheel spokes, chair legs, canoe paddles, bows, and the like.

The result of using two hands is an even application of the tool that turns it into a sort of plane.

This makes it perfect to use on larger surfaces compared to the standard flat scraper.

What are They Made From?

Cabinet scrapers are made from very hard materials to withstand plenty of abrading and grinding work throughout their working lives.

These materials include:

- Cast iron

- Nickel-chromium steel

- Medium to high carbon steel

These materials can be used for scraping work for a long time without easily becoming damaged.

To make these card scrapers even tougher and stronger, they are also polished via methods like cold rolling, hardening, and tampering.

What are Cabinet Scrapers Used for?

Put simply; a cabinet scraper is used to remove small amounts of wood or old finish from the surface of items that are made from wood.

The scrapers come in several different types that can be used to match the shape of the surface it is scraping.

Plus, the scraper is easy enough to handle, so you can shape the surface depending on your needs.

For the most part, scrapers are used on furniture, musical instruments (such as guitars and violins), and other items made from wood, including cabinets.

You can find scrapers that fit unique shapes such as convex or concave, along with standard flat scrapers.

One advantage that a scraper has over sandpaper is that it does not dull the surface. The sandpaper will create tiny scratches where dust will collect.

The result is a surface that does not shine. However, a scraper will smooth out surfaces without creating tiny scratches.

This makes them perfect for jobs where you want to maintain the appearance of the surface without using sandpaper.

How to Choose the Right Cabinet Scraper?

For the most part, the factors involved in choosing the right cabinet scraper start with the type of surface, the size of the surface, the amount you intend on using the scraper, and the price you are willing to pay.

a) Use: Scrapers are generally inexpensive, which is why they often come in sets.

If you plan on scraping surfaces with a degree of regularity, you should consider getting a set of scrapers.

However, if you only intend on scraping one type of surface for the foreseeable future, such as a flat surface, you only need a flat cabinet scraper.

The more you use scrapers, the more likely you are to purchase a set. Go for the high-quality versions with a strong reputation for maintaining their integrity.

b) Size: The range of sizes is not that broad in these hand tools, but it is considerable enough that you need to choose wisely.

Mini scrapers are best for small or specific surfaces, while larger ones are best for wider areas.

Choose the type that is best suited to your needs. If you work with a wide range of surfaces, then you will need both smaller and larger scrapers.

There is no universal scraper. You will need to use the best size for the surface. Otherwise, you may risk damaging the material.

c) Cost: The price of the scrapers should be the tiebreaker when making your consideration.

This means with the quality being equal; you should choose the least expensive scraper or set.

Purchasing individual scrapers usually is pretty cheap. It is when you purchase a set that things become more complicated.

However, just because one scraper set is more expensive than the other does not mean it is better.

But if you are going to use the scrapers frequently, then it does pay to get a high-quality set.

Consider adding other tools that will help you maintain your scrapers, such as a file and sharpening stone to maintain a sharp edge.

And vice to hold the scraper when sharpening.

How Do You Sharpen a Cabinet Scraper Blade?

When you start noticing nicks or chips in the scraper blade.

Or, when the scraper becomes harder to run across the surface and starts producing sawdust instead of just shavings, it is time to sharpen the scraper.

Consider that a flat scraper normally has a large surface, so you can sharpen it fairly frequently until you can no longer comfortably hold the tool.

This is because sharpening involves removing material from the scraper until it is sharp again.

However, smaller scrapers such as curved, convex, or concave have a considerably smaller amount of material.

This means that when sharpening, you will quickly reduce the material until it can no longer be comfortably held.

A diamond stone is a popular tool for sharpening and works well on a cabinet scraper. Just follow these steps.

- Set the scraper in a vice

- Use a marker pen to mark the edge being scraped

- A mill file will remove the nicks and smooth out the edge

- Hold the mill file at both ends, angle it to the edge you want to create, and run it across the surface

- Check the smoothness of the edge after filing

- Push the scraper along the diamond block until it gets a really sharp edge

What Alternative to Use when You do not Have a Cabinet Scraper?

The two most common items that can be used in the place of a cabinet scraper are sandpaper and a plane.

The sandpaper will make the surface smoother when you use a fine grit. But it can dull the surface.

Also, sandpapers are slow, require a lot of energy when sanding surfaces, and wear down very quickly.

Cabinet scrapers are much better in this respect as they stay remain sharp for longer and can also be re-sharpened.

A plane, on the other hand, is designed to work well on larger surfaces and will work better than sandpaper or a cabinet scraper if you have a larger project.

But it’s ill-suited for smaller surfaces, especially curved ones or other hard-to-reach surfaces.

FAQs

Can cabinet scrapers be repaired?

Yes, you can repair your cutting-edge cabinet scrapers by grinding if they get chipped.

If, however, a scraper gets bent or cracked, it cannot be repaired and should be replaced.

Blades of a two-handled cabinet scraper are sold separately, and they can also be replaced if it becomes damaged.

How to care for your cabinet scrapers?

To make your scraper last longer, you can simply wipe down the tool with a clean cloth to remove any oil or debris.

Then keep the metal scraper tool in a safe, dry place to avoid damage.

Cabinet scraper vs. card scraper: what’s the difference?

The terms cabinet scraper and card scrapers are often used interchangeably by many DIY woodworkers and carpenters.

Both these tools may be thought to be similar, but they are not because there are differences in their shape and how they are made.

A card scraper is basically shaped like a card, while a cabinet scraper comes with grips.

Unlike card scrapers, cabinet scrapers are not designed to leave a finished surface.

Instead, they are used to remove machining marks (or any tracks and tear-outs) that may be created by the hand planes or jointer and planer.

Final Thoughts

A Cabinet scraper is a versatile tool for woodworkers that can help to smooth, flatten, shape, refinish or reduce the thickness of the wood surface.

Unlike sandpapers, it does not leave a duller effect on the surface.

And it’s more effective than wood planes when you need to scrape at tight corners, in different directions, and at a variety of angles.

Based on your project type, you can choose from the different types of scrapers and get your job done within no time.

All you will get is a silky-smooth finish with beautiful grain patterns intact.

Share the post "What is a Cabinet Scraper – Different Types and Uses?"

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.