If you remember the first time you stripped a screw, you know how difficult it can be to remove it.

Given the sheer number of screwheads that are on the market, it pays to know the differences.

That way, you can avoid stripping the screwhead because you have the right tool for the job.

What follows is a complete guide to the different types of screwheads that are available. So be patient and check them out before you make a purchase…

Types of Screw Heads

You may be surprised at the number of different types of screws that exist. No matter the job, there is a screwhead designed for a specific purpose.

Especially if you are new to woodworking or construction, it can be difficult to know which type of screwhead is best for your needs and which one to choose for your specific task.

With the different types of heads and drivers, it’s not only complicated but expensive as well.

So, it is essential to understand the different types that are out there – both in terms of the shape and what each one of these does.

1- Countersunk Screw Heads

Countersinking is a popular method used to prevent splitting the wood when drilling.

With a countersunk bit, you can create the pilot hole and the proper angle needed to ensure the screw enters the right way.

This is the process used to create the correct angle for the head of the screw. The result is a professional appearance to your project.

Because of their shape and angle, some screwheads will require countersinking. Such head shapes that require countersinking include the following.

a) Flat:

A flat screw head sits flush with the surface with none of the head is exposed. You will need to countersink them to get the proper use of the screwhead.

Because the screws will not stick out from the surface, they will not catch on to things that may pass over the material.

So, if you are creating an item that people may encounter, such as a sofa, bookshelf, or the like, a flat screwhead will be of considerable benefit.

And if you use a screw cover, you will not see the screw head.

Flat head screws have different degrees that you need to be aware of.

The degree refers to the angle from the top of the head to the surface where the threaded part meets the head.

The standard angle is 82 degrees, but there are different degrees which include 90, 100, and others.

The higher the degree, the shorter and more spread out must the countersink hole be.

A flat undercut 82-degree head is the same angle as the standard version. The difference is that the head itself is considerably shorter.

The shape of the head gives the screw a longer thread even though the length of the screw is the same.

b) Raised:

Sometimes known as oval-shaped, these screwheads have an angle like flat heads but are more rounded or dome in terms of shape.

These screws will require a countersink as well to accommodate the angle of the screw.

As the name suggests, the raised screw will stick above the surface to a greater degree than a flat screw.

The shape is more for decorative purposes compared to the flathead.

c) Bugle:

The shape of the bugle screwhead is like a flat head.

The only difference is the angle that is below the surface. It is a curved shape designed to limit the damage to the material.

This type of screwhead is designed for drywall and plasterboards.

Because they are self-drilling, bugle screws do not need pilot holes. Their unique shape distributes the stress across a wider surface when compared to flat screws.

2- Non-Countersunk Screw Heads

There is no angle with the shape of the head when looking at non-countersunk screw heads.

They sit outside the surface of the material. This means there is no need to create an angle for the screw head itself.

a) Binding:

These are unique types of screws that can be used for many different projects.

They are distinguished by their slightly domed head and can mate with each other using the male and female sides.

This type of screw is often used to hold together leather, swatches, and similar materials.

But they can also be used to keep bookbinding projects and large manuals together as well, hence the name.

b) Domed:

One of the most common types of screws that you’ll find, domed screw heads are used when you do not need a flat head to be hidden on the surface.

The screw heads protrude from the material for a reason. For example, on a sofa where the domed screw heads are above the fabric and provide a decorative touch.

While the domed shape has visual appeal, the flat inner part creates the screw stop that rests the screw head right at the surface.

c) Flange:

Sometimes called frame screws, the heads of this type of screw vary from hexes to circular.

The head will jut outwards from the flange, which is circular to directly underneath the head.

Depending on the project, the flange keeps the screw in place and can replace the washer.

d) Truss:

These are wider compared to the heads of other types of screws.

Truss heads have a slightly rounded surface and are often used with sheet metal and other projects that require wider holes.

This is because the broad head of the truss screw is large enough to prevent it from going through larger-than-normal holes.

3- Combination Type Screw Heads

Arguably the most common type of screw head, you will find considerable variations and combinations of this type.

If you look at the head, you will see if they are countersink or non-countersunk in design, so pay attention to the head before you make the purchase.

Screwheads that require a countersink will have an angular shape under the head. While non-countersunk designs will be flat.

So, if you want the screw heads to be flat against the surface or stick out, you must decide which type of use.

There is no lack of variations available; you will simply need to know what you want before you begin.

4- Tamper-Resistant Screws

For the most part, tamper-resistant screws are variations of the standard screw heads that are listed in this article.

As the name suggests, this type of screw is mainly used for items that might otherwise be stolen or torn apart.

You’ll often see them in public restrooms or used with expensive fixtures. Each type of tamper-resistant screw offers its characteristics.

a) Pin:

Made from stainless steel, these pin screws are tamper-proof and come with a button head sheet.

Many have the same characteristics as a Phillips screw head but an extra layer of security that does not allow a Phillips screwdriver to use them.

You will need a specialized screwdriver to drive in or remove the pin screws.

b) Sentinel:

This is a countersunk screw that uses a sentinel head. Because you can only drive them one way, taking them out is quite tricky.

Because of this, only use this type of screw when you are sure you will never take the item apart.

c) Two-Hole:

Sometimes called a two-hole spanner, have a sharp finished look that still provides plenty of security.

While they look like a typical flathead design, they have two holes in the groove that must be contacted for them to be appropriately driven into the material.

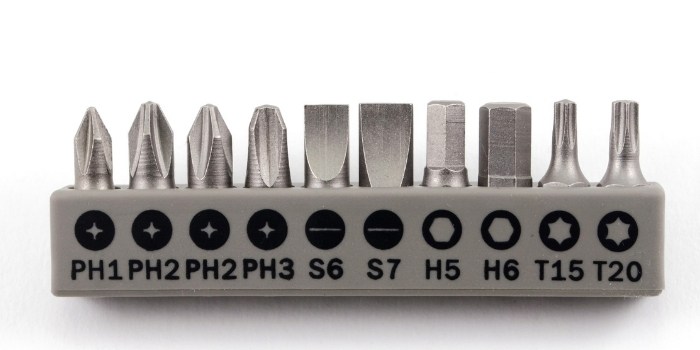

5- Screwhead Drive Types

This refers to the type of tool needed to drive in the screws.

Because of the different shapes and heads, you need the correct type of screwdriver.

Because the drive directly relates to how the screw attaches to the surface, some drivers are better at avoiding stripping than others.

However, there are some types of screw heads that are so expensive as not to be worth getting the proper tool.

a) Hex External:

As the name implies, the external hex screw features a hex shape.

Such screw heads protrude from the surface, and some will have external flanges, although many retain the classic hex shape.

This type of screw requires a socket or standard wrench to drive into or pull out from the material. Because of their design, you can apply more leverage.

b) Hex Internal:

Here, the hex shape is on the inside of the screw head.

This requires an Allen wrench to either drive in or remove. These are popular screws for items that must be assembled.

This is because the Allen wrench is far less likely to cause damage than a flat head or Phillips screwdriver.

In fact, if you order an item that requires assembly and uses hex internal screws, the Allen wrench often comes with the package.

c) Phillips:

One of the most commonly available is the cross-shape screw head. This requires a Phillips screwdriver to either drive into or remove from the material.

One big advantage is that you can use a powered screwdriver because the cross-shape keeps the driver in the middle of the screw head.

However, if you use too much force in either driving in or removing the screw, then you may strip it.

d) Pozidrive:

This type of screw head looks like the Phillips, except that it has a few more grooves that make it appear star-shaped.

Using a Phillips screwdriver for some, but not all, the Pozidrive screw heads are possible.

You can tell their difference when looking at the ribs between the four extensions. You’ll see that they are marked with the letters “Pz.”

They have an advantage over the Phillips screw heads thanks to their additional grooves, which add more stability.

However, they require a specific screwdriver that may be more difficult or expensive.

e) Quadrex:

This is sometimes called a Phillips square drive. It looks like a Phillips cross design, but the middle is not properly crossed but square in shape.

This is good because the square helps prevent the screw head from being stripped when too much force is applied.

f) Slotted:

You probably know the slotted screw head better than the flathead screw. One long slit allows for the flat screwdriver to be inserted.

One of the most common and inexpensive screwdrivers and screw heads on the market, they suffer from being stripped due to their design.

In fact, it is part of the design that slotted screw heads will strip relatively quickly when too much force is applied. This prevents overtightening.

You should use a manual screwdriver instead of a powered one when driving in or removing a slotted screw.

g) Square Recess:

You may have heard this type of screw head referred to as a Robertsons. The square center prevents cam outs.

The advantage is that the bit that drives the screws comes out of a square taper.

The result is a design that is self-holding and, thus, faster to apply since you do not need to use your free hand to hold it in place.

h) Star:

As the name suggests, the shape is that of a star. One common star design consists of two Robertsons that form an 8-point star in the center.

This means that you can use a Robertsons screwdriver to drive in or remove the screw. Or you can use a special 8-pointed design if you need to apply more force.

In addition to the 8-pointed design, there is a 12-pointed one as well as triple Robertsons.

The triple squares allow you to apply even more force when you use the proper screwdriver. You’ll find this type of screwhead most used in automobile parts.

i) TORX:

While the name may not seem familiar, this is one of the most common screw heads in use today.

You’ll find TORX screws used in many electronic devices. They consist of a 6-point star shape found in the middle of the screw head.

They are popular in electronics because their shape helps prevent cam-out situations. When constructing an electronic device, this can be most helpful.

j) TORX Plus:

This type of screw head looks like a TORX but has shallower grooves located between the points.

This allows the screwdriver to have better contact with the screw head. The result is that you can apply more force with a TORX Plus compared to the standard TORX.

k) Tri-Wing:

This is a screw that came out on the market more recently than most other screw heads on this list.

This is a stainless steel version of a Truss head that allows for more force to be applied when driving in the screw.

This means greater stability compared to many other types of screw heads. However, this specialized version can be either expensive or hard to find.

Choosing the Right Screwheads

When picking the right screwhead for your specific woodworking project, the first difference to understand is whether the screw is countersunk or non-countersunk and the different types of screwheads available for each type.

You may not consider the shape of the screwhead to be all that important. But there is a reason why each screwhead is made into a particular shape.

Understanding the reasons will help you choose the best one for the job. This allows you to complete the project faster and includes the preferred method to finish it as well.

For example, the screwhead may sit above the material’s surface or sink until it is flush with the surface.

In addition, the shape of some screwheads may add to the aesthetic value of the project, while with others, it does not matter.

The shape of the screwhead may also dictate the type of force and mechanics needed to implant the screw fully.

Matching Screwheads to Materials and Projects

If you do not need a particular screw or matching bit, you certainly do not want to spend any money on them.

It’s best to find the right type of screw head and the matching bit that fits with the project you have in mind.

For simpler projects that do not require that much force, a flat head or Phillips is an excellent type to use.

They are inexpensive and quite effective for simple wood projects that can be driven manually or with a power tool.

For complicated projects using harder materials, you will want to use a TORX, Tri-Wing, or similar screw with more points. This allows you to use more force when driving in the screw.

To purchase woodworking screws, you can go to your local hardware store or purchase the screws you want online. Stick to recognized dealers in the field when purchasing such items.

This means Amazon, Lowe’s, or Home Depot, which allow for online purchases.

Remember that the more common the screw head, the lower the price. The more complicated the screw head, the more you are likely to pay.

But you may get your money’s worth by not stripping out the head when you pay for the best.

Share the post "Different Types of Screw Heads for Woodworking [Complete List]"

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.