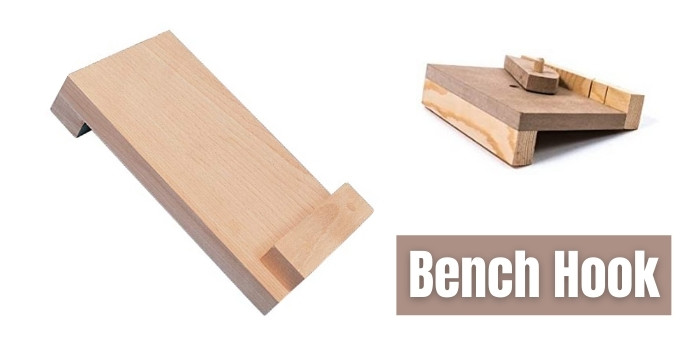

A bench hook is one of the simplest yet most commonly used accessories in a woodworking shop. Its job is to hold a piece of wood firmly while it is being cut on a workbench.

There are no moving parts, no sophisticated pieces; it is only a support to hold the wood while it is being cut by a saw.

As simple as the function of a bench hook is, its attributes are considerable.

- Prevents Errors

- Improves Precision

- Increases Safety

And while most of the cutting is performed by a saw, you can use a bench hook to secure the wood when using a chisel or a plane.

Its versatility is what helps make it a popular device in the workshop.

How Does it Work?

When looking at a bench hook, the first thought maybe that it does not look like a typical hook.

And yet the name has stuck because one end is secured or “hooked” to the end of the workbench or table.

Essentially, it consists of three pieces of wood. A large flat piece that holds the wood on top. And two small pieces that can be found at either end.

One small piece is on the bottom of the flat piece. It hooks to the side of the table, securing the bench hook.

While the other piece is on the top and opposite side of the flat piece, it holds the wood in place when it is being manipulated.

The pressure applied to the wood that is being cut or manipulated against the top piece of the bench hook pushes the bottom piece against the side of the table.

This is what secures the wood and allows for sharp cuts, marks, or chiseling to take place.

What is it Made of?

A bench hook is made from solid wood and can be purchased at a typical hardware store.

However, it is so simple in construction that many people make a bench hook themselves.

A standard bench hook can be made from wood, plastic, or metal. But most bench hooks are made from wood because they are often homemade. But it also shows just how versatile wood can be.

Bench hooks are often crafted from hardwood. This is because hardwood is stronger and more durable compared to softwood.

It also means that a hardwood bench hook will last for many years of normal use. Plus, it allows you to cut a wide range of wood without causing damage to the hook itself.

You can create a bench hook out of softwood or purchase a plastic version.

But the pressure that is applied to keep the wood being cut in place may snap a bench hook that is made from inferior materials.

You are simply better off purchasing a hardwood or metal bench hook as they hold up under greater pressure for longer periods.

If you are making a bench hook out of hardwood, you will need the right type of stops or fasteners that holds the smaller pieces to the large, flat piece.

The three most common types of fasteners are screws, glue, and dowels. Nails tend to bend and become undone, making them a poor choice as fasteners.

While screws are better than nails, you may be surprised at how well dowels work to hold the pieces of a bench hook together.

If you are using glue, be sure it is a strong glue evenly applied across the surface. This will form the tightest bond, but glues can dry out over time.

So, consider using dowels as the main fasteners for your bench hook.

The Parts of a Bench Hook

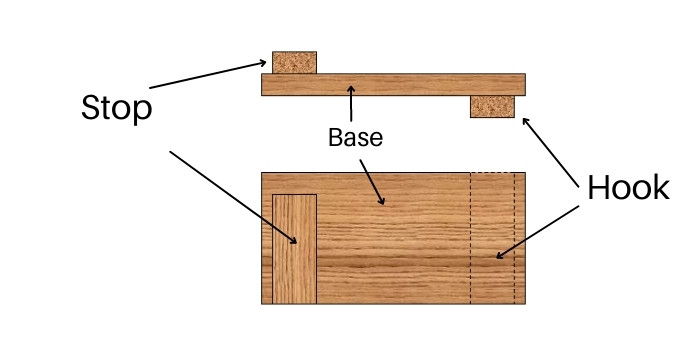

There are three parts to a bench hook. All three parts or pieces are normally made from the same material.

- Base

- Stop

- Hook

The base or bed of the bench hook is the flat surface that will support the wood you are cutting, chiseling, or manipulating.

There is no exact size of a bed, but it tends to be 6” wide by 10” long. You can make or purchase one that is larger or smaller, depending on your needs.

The stop is also known as the fence or front batten. It is normally about an inch or so shorter compared to the width of the base and is offset to one side. This gap allows for the sawing of the wood to take place.

You position the board that you want to cut against the stop so that it lines up with the edge. The forward pressure on the bench hook will keep it in place.

The part of the stop against which the wood is held is known as the face. The face is usually set straight up or 90 degrees from the base.

However, sometimes they are raked in which the face is either less or greater than 90 degrees.

A face that is greater than 90 degrees acts more like a hook itself to hold the wood or workpiece in place.

However, a more practical application of the face which is greater than 90 degrees, is that it allows the sawdust that is formed not to interfere with the positioning of the wood.

Otherwise, the connection point between the face and base would have to be regularly cleaned.

How to Use a Bench Hook Tool?

The best way to secure the stop to the base is by using dowels. Although you can use screws or glue, dowels are actually better.

To add the dowels, you will need to drill holes in the stop and the base, which are slightly smaller than the dowels being used.

Then pound the dowels through the holes and saw off the excess. You can add glue inside the holes before adding the dowels for greater strength.

The hook is also called the rear or lower batten. It is placed on the opposite side of the stop and on the bottom of the base, not the top.

The hook is used to secure the base to the table or workbench. When the pressure is placed by the workpiece on the face of the stop, it presses the hook into the side of the table or workbench.

The hook is secured to the base in the same manner as the stop. Plus, the hook usually extends the full width of the base and does not stop short like the stop. This is usually done to differentiate the stop visually from the hook.

But you can make it reversible by making the hook the same length as the stop so the bench hook can be flipped when needed.

Choosing the Right Bench Hook for Your Job

The first tip in selecting the right bench hook is to find one that fits your specific needs.

A simple, no-frills bench hook can be made easily enough with the right pieces of hardwood and dowels. But if you need something specific on your bench hook, then a simple one will do.

Left or Right-Handed:

Get a bench hook that is best suited for your lead hand. This is normally determined by how the stop is set on the base, either to the left or right side.

Of course, you can always get a reversible bench hook in which the stop has equal openings on both sides.

A reversible bench hook also extends the life of the base since you are using both sides. This means less wear.

Tips for Caring & Maintenance of a Bench Hook

Bench hooks will suffer damage as saws, chisels, and planes used on the workpiece will pierce into the base and stop.

To care for and maintain your bench hook, you should wipe it down and perform minor repairs to the surface when needed.

Drill a small hole in the base near the stop so that you can hang the bench hook when not in use. Keep the bench hook out of the sunlight so it is not affected by UV rays.

You should also keep replacement parts around, such as the hook and stop, in case they suffer damage extensive enough to require being replaced.

However, if your bench hook uses dowels and/or glue to keep the hook and stop in place, it will make both parts more difficult to replace. You will need to use screws instead.

Instead, you may want to keep the parts around to create another bench hook when your current one has seen better days. That way, you can create the type of bench hook needed for your tasks.

Share the post "What is a Bench Hook – How to Use it for Woodworking?"

Hi, I am Mark Garner a professional carpenter, woodworker, and DIY painter. I live in the small city of Peoria, Arizona as a semi-retired woodworker. I have started this blog with a simple motive to help you with my wood experience in this sector. If you like to know more about what I love doing and how it all got started, you can check more about me here.